Clemson Vehicle Assembly Center

The Clemson VAC is an environment where students can develop and test prototypes in a realistic manufacturing setting, free from production pressure.

SmartState Lab Awards

-

NSF Graduate Research Fellowship Honorable Mention (2019), Tyler

-

NSF Graduate Research Fellowship (2017-2020), Brandt

-

Fellow of SME (2017), Mears

-

Fellow of the ASME (2016), Mears

-

BMW SmartState Chaired Professor of Automotive Manufacturing (2016-), Mears

-

Institution of Mechanical Engineers (UK) Thatcher Brothers Prize, awarded for the best paper on a manufacturing industries subject (2016), Yujie

-

Clemson University College of Eng. and Science Dean’s Professorship (2015-2018), Mears

-

Autodesk® Fusion 360™ student design challenge award (2016), Farbod

-

Clemson University R.C. Edwards Fellowship (2015-2017), Brandt

-

US Dept. of Defense / National Center for Defense Manufacturing and Machining MTConnect Challenge Part 2 First Prize (2014), Valerie

-

Clemson College of Engineering and Science Outstanding Young Alumni Award (2014), Mathew

-

Clemson Mechanical Engineering Excellence in Engineering Award, given for the top undergraduate honors research project (2014), Elizabeth

-

Clemson University College of Engineering and Science Graduate Research and Discovery Symposium poster competition second place (2014), Farbod

-

ASME Manufacturing Science and Engineering Conference Best Paper Award, 3rd place (2014), Kavit

-

SAGE Journal of Engineering Manufacture Top 5 Most Downloaded Paper (2013), Wes

-

Institute of Mechanical Engineers (UK) George Stephenson Gold Medal (2013), Wes, Cristina

-

Clemson College of Engineering and Science McQueen Quattlebaum Faculty Achievement Award for leadership in the engineering profession (2013), Mears

-

SAGE Publishing Best Paper Prize, Journal of Engineering Manufacture (2012), Wes

-

Society of Manufacturing Engineers (SME) E. Wayne Kay Graduate Scholarship (2011, 2012), Josh, Wes

-

Automotive Engineering Department Outstanding PhD Student (2012), Wes

-

Clemson MSE Department Best Student Presentation Award (2012), Mathew

-

Clemson University Board of Trustees Award for Faculty Excellence (2012), Mears

-

SME Schneider-Bingle Endowed Scholarship (2011), Josh

-

Clemson Distinguished Graduate Student Research Fellowship (2011), Wes

-

Clemson University Board of Trustees Award for Faculty Excellence (2011), Mears

-

NSF Graduate Research Fellowship Honorable Mention (2010, 2011), Wes

-

Society of Automotive Engineers Ralph R. Teetor Educational Award (2011), Mears

-

South Carolina Governor’s Young Researcher Award for Excellence in Scientific Research (2011), Mears

-

Clemson College of Engineering and Science Collaboration Award (2010), Mears, Mayorga

-

NSF CAREER Award (2010), Mears

Lab News

Harshada wins Sage Fellowship

Congratulations to Harshada for winning the Sage Fellowship in Automotive Engineering!

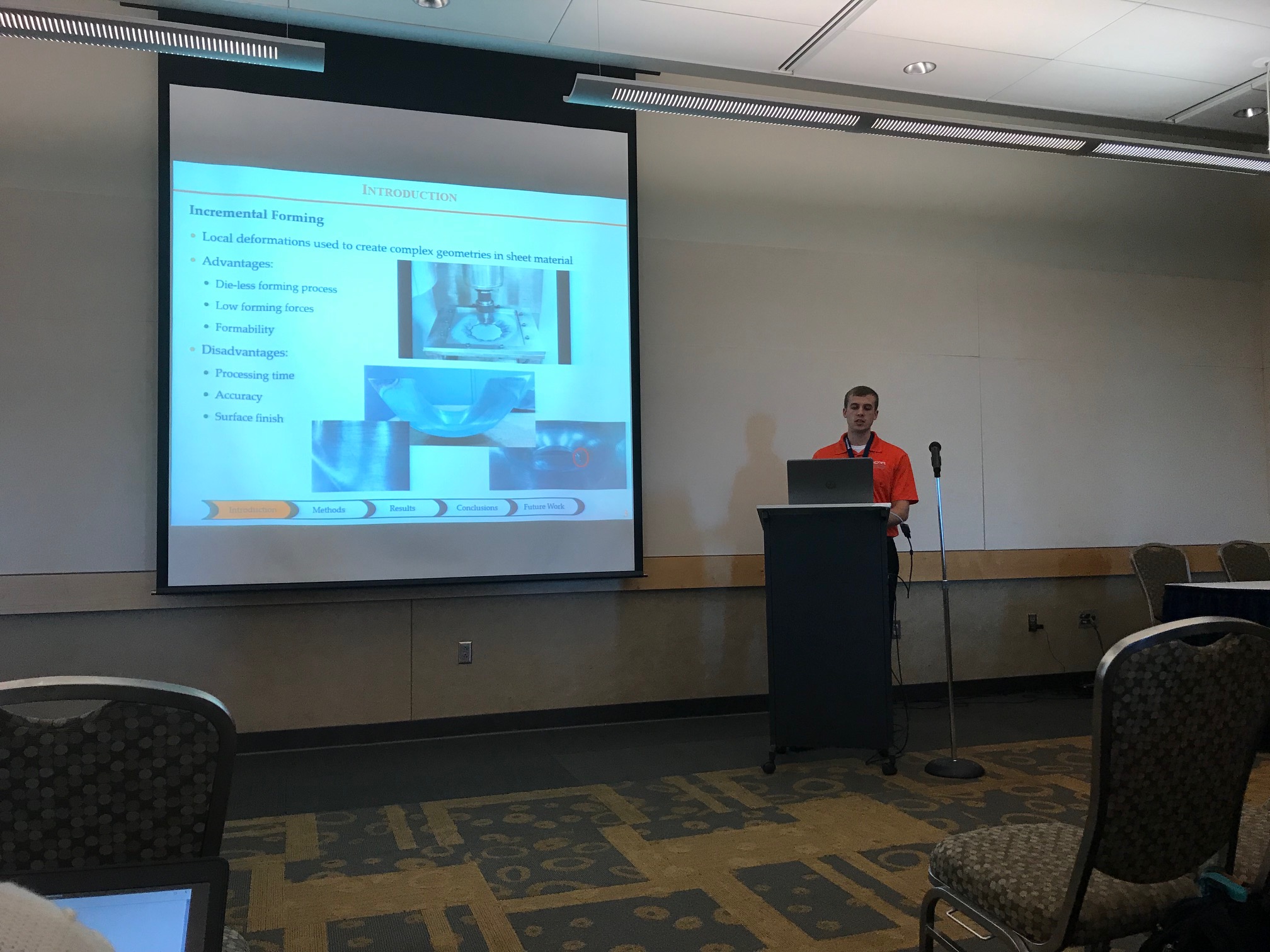

Congratulations Tyler at IMECE

Tyler presented 3 papers and a poster at the 2019 ASME IMECE Conference, and was awarded Honorable [...]

Governor McMaster Launches Fraunhofer Alliance

Governor McMaster held the ribbon cutting for the new Fraunhofer Alliance in South Carolina. We have been [...]