3 wet hoods from Salare Systems in NC for solvent, acid & base etching and wafer cleaning

Typical processes

Additional Wet hoods

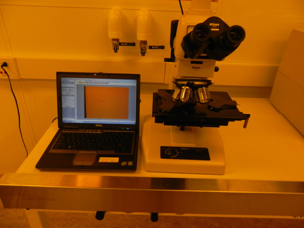

Brewer Sciences Photo Resist Developer Tool

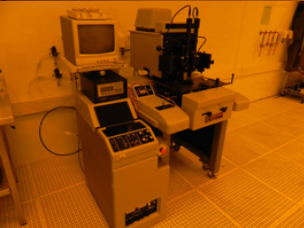

Nuetronix/Quintel 1X Contact/Proximity Printer

Model Q-7000-IR

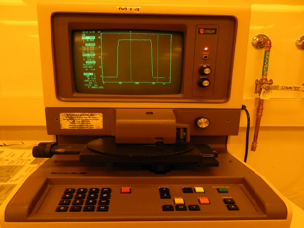

GCA 5:1 Reduction i-line optical stepper

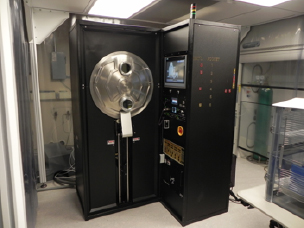

PlasmaTherm Versaline ICP

Oxford Instruments Plasmalab 100 ICP

Atomic Layer Deposition (ALD)

Oxford Instruments OPAL ALD tool utilizing the following pre-cursors:

Electron Beam Deposition

Metals

Dielectrics

K&S Wafer Dicing Saw

K&S Wire Bonder

Custom tooling fees are charged on a tool by tool basis depending on the complexity of design and material needed.