APS Facilities

Advanced Powertrain Systems Facilities

Renk Labeco 4-Wheel 500 HP Chassis Dyno and Faist Semi-Anechoic Chamber*

Renk Labeco 4-Wheel 500 HP Chassis Dyno and Faist Semi-Anechoic Chamber*

The Renk system is a low-noise chassis dynamometer housed in a semi-anechoic chamber, making it able to perform driveline noise studies, fuel mileage assessments, sound measurements and all other chassis dynamometer and sound room-related test activities. We have several data acquisition and sensor systems available in this laboratory, including emissions analyzers, engine crank-angle resolved data acquisition and sensors, fuel flow rate measurement, sound characterization equipment, and a driver aid system for carrying out specific drive cycles (e.g., US06, FTP, etc.).

MTS 320 Tire Coupled Road Simulator and Weiss Climate Test Chamber*

MTS 320 Tire Coupled Road Simulator and Weiss Climate Test Chamber*

This facility will support testing for squeaks and rattles, vibration, structural durability, suspension characterization and fastener integrity. The road simulator is in an environmental chamber, allowing for many unique testing possibilities.

FEV 500 HP Engine Dyno Test Cell*

FEV 500 HP Engine Dyno Test Cell*

A containerized and expandable facility, this system accommodates testing of performance, engine durability and components, emissions, fuel, catalysts, and engine mapping and calibration.

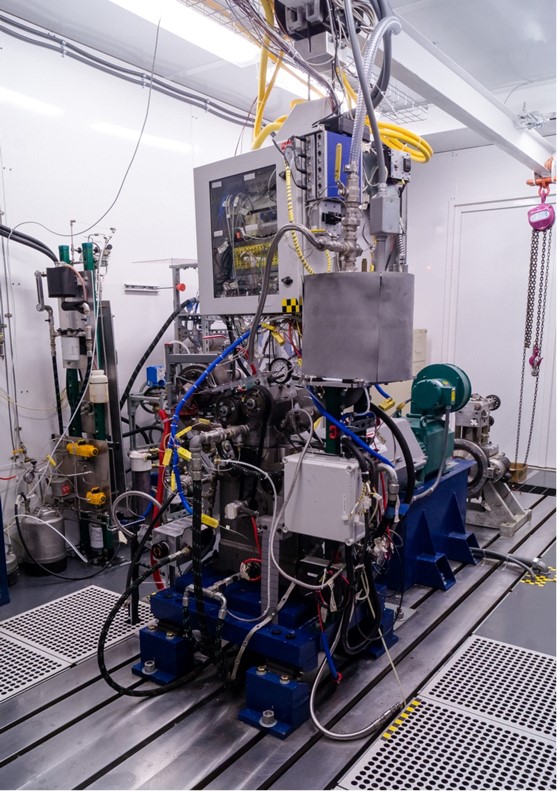

Advanced Combustion and Heat Transfer Laboratory

Advanced Combustion and Heat Transfer Laboratory

A 100 hp, double-ended Baldor motor controlled by an ABB four-quadrant drive, combined with fluid conditioning systems, an accumulator-based high-pressure injection system, and a sixteen-channel AVL IndiSet crank angle resolved data acquisition system, to provide everything necessary for advanced combustion and in-cylinder heat transfer studies.

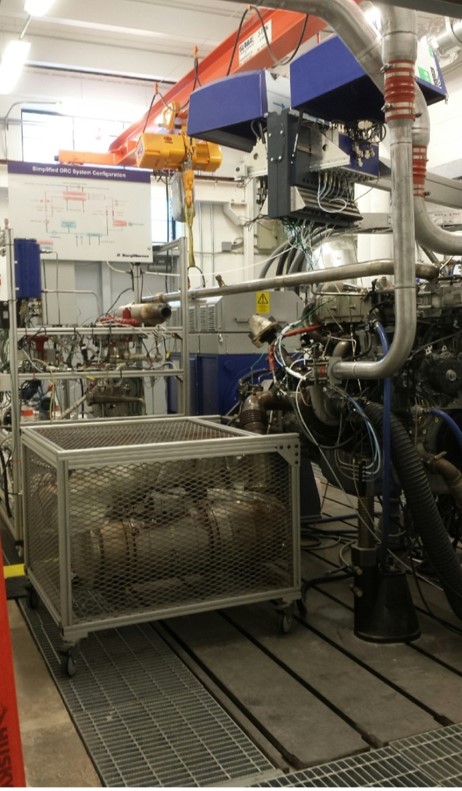

Advanced Powertrain Laboratory

Advanced Powertrain Laboratory

A fully transient, double-ended, AVL 440kW engine dyno capable of testing multiple hybrid configurations through a combination of conventional engines and electric motors. Time-resolved signals are synchronized with crank angle-resolved data acquisition through the AVL PUMA test coordination system. Full gaseous emissions characterization can be conducted with an AVL FTIR, while the Cambustion DMS 500 provides transient particulate size distributions. Either gasoline or diesel-powered concepts can be accommodated with natural gas fueling capability arriving soon.

Machine Shop*

Machine Shop*

A well-equipped machine shop with turning, milling, drilling, sawing, welding and plasma cutting capabilities is located within the Campbell Center.

General-Purpose Lab Area

General-Purpose Lab Area

The laboratory, which is not available to the public, has a large general-purpose high bay area with a 5-ton overhead crane and two Rotary vehicle lifts. One is a two-arm 10,000 lb. capacity lift, and the other is a four-post 14,000 lb. capacity alignment lift.

Okuma MU-500 5-Axis Machining Center

The MU-500 is a universal machining center, able to remove material in any accessible orientation to the cutter. It allows for cutting of freeform surface geometry and is also driven by the Okuma THINC controller.

Data Acquisition and Instrumentation Services Tools*

The Campbell Center is equipped with a full range of vehicle instrumentation and data acquisition tools. The staff has extensive experience with in-vehicle measurements for both on- and off-road operations.

*These facilities may be rented for testing needs.