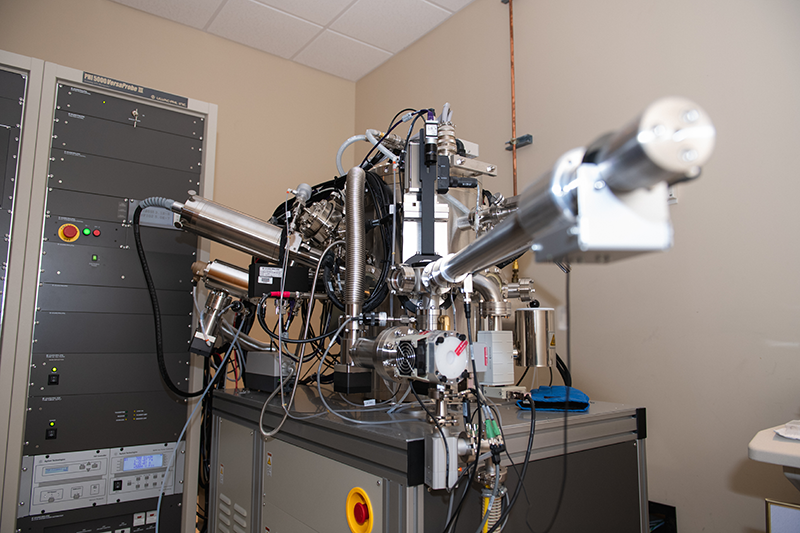

X-Ray Photoelectron Spectroscopy (XPS) – PHI VPIII

Instrument Specifications

Chemical quantification and chemical bonding information from the top ~ 10 nm

- Angle Resolved analysis between 1nm – 10 nm

- Ar ion etching (metals / SC)

- C60+ etching (polymers)

- In situ heating and cooling

- Chemical mapping resolution approximately ~ 10 μm

Applications

- Quantify atomic ratio >0.1%

- Identify chemical bonding and valence state

- Depth profile to identify how these factors change through the bulk of the material

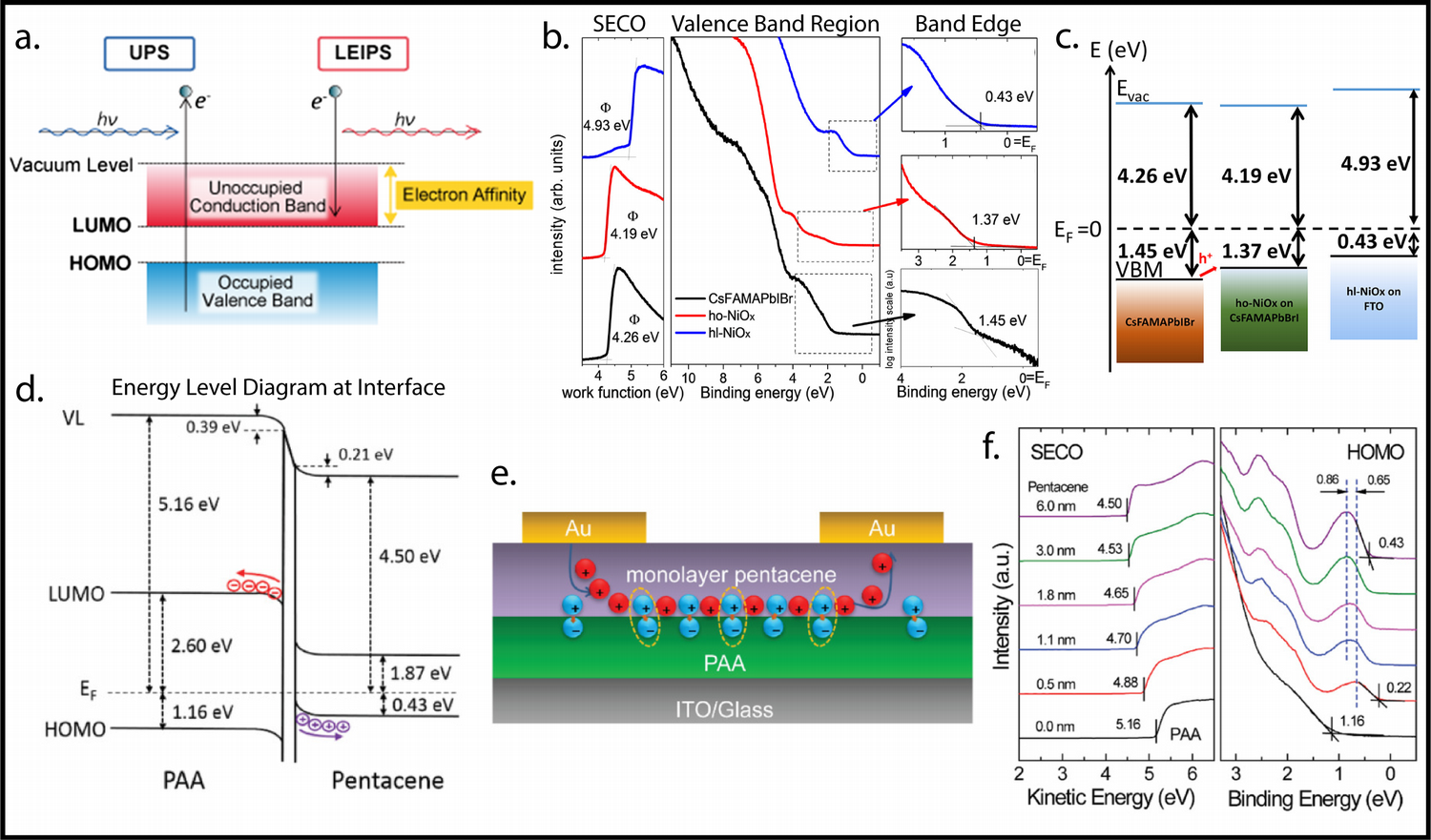

- This can be run in tandem with AES, UPS, LEIPS

- This can be correlated with TOF-SIMS analysis

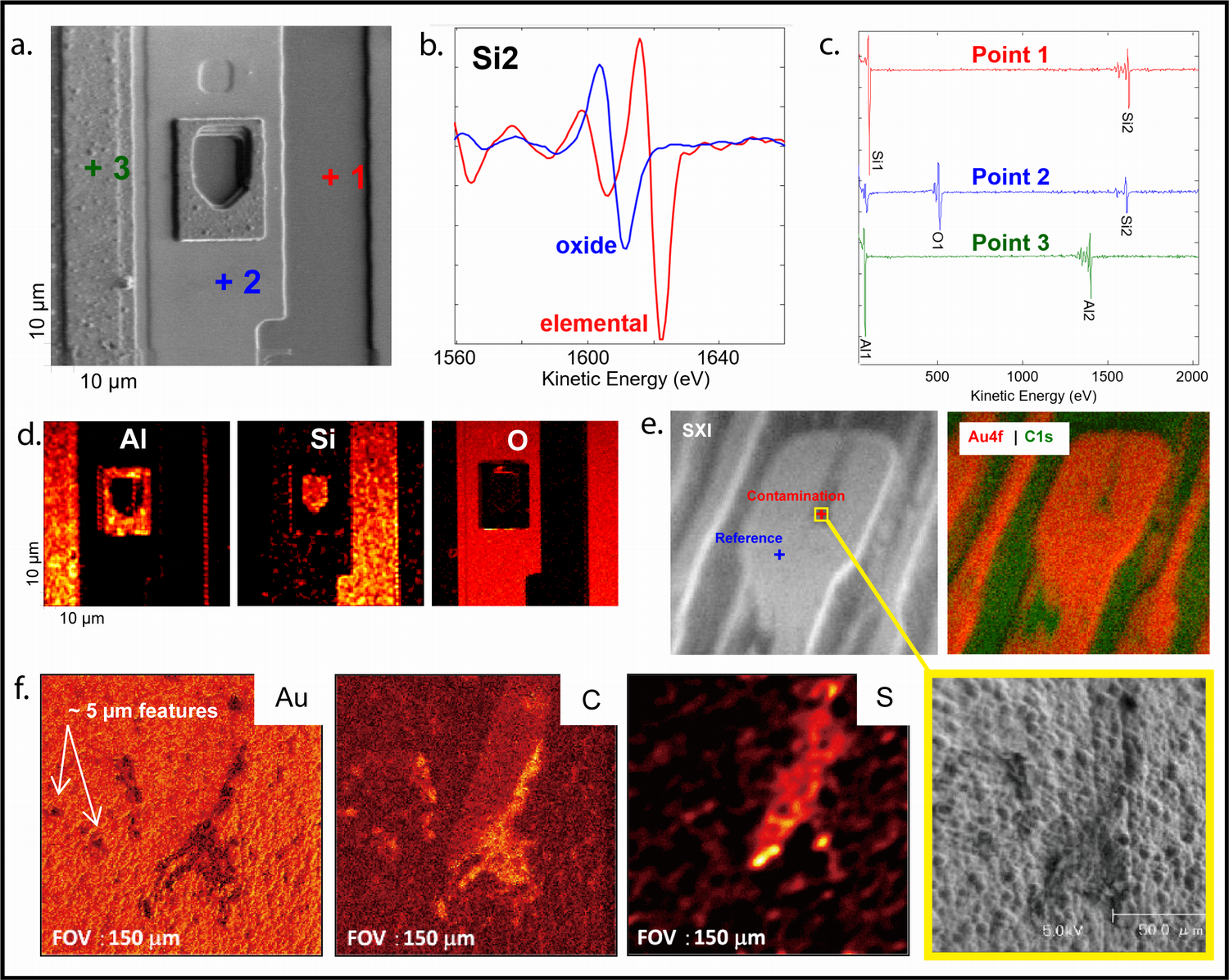

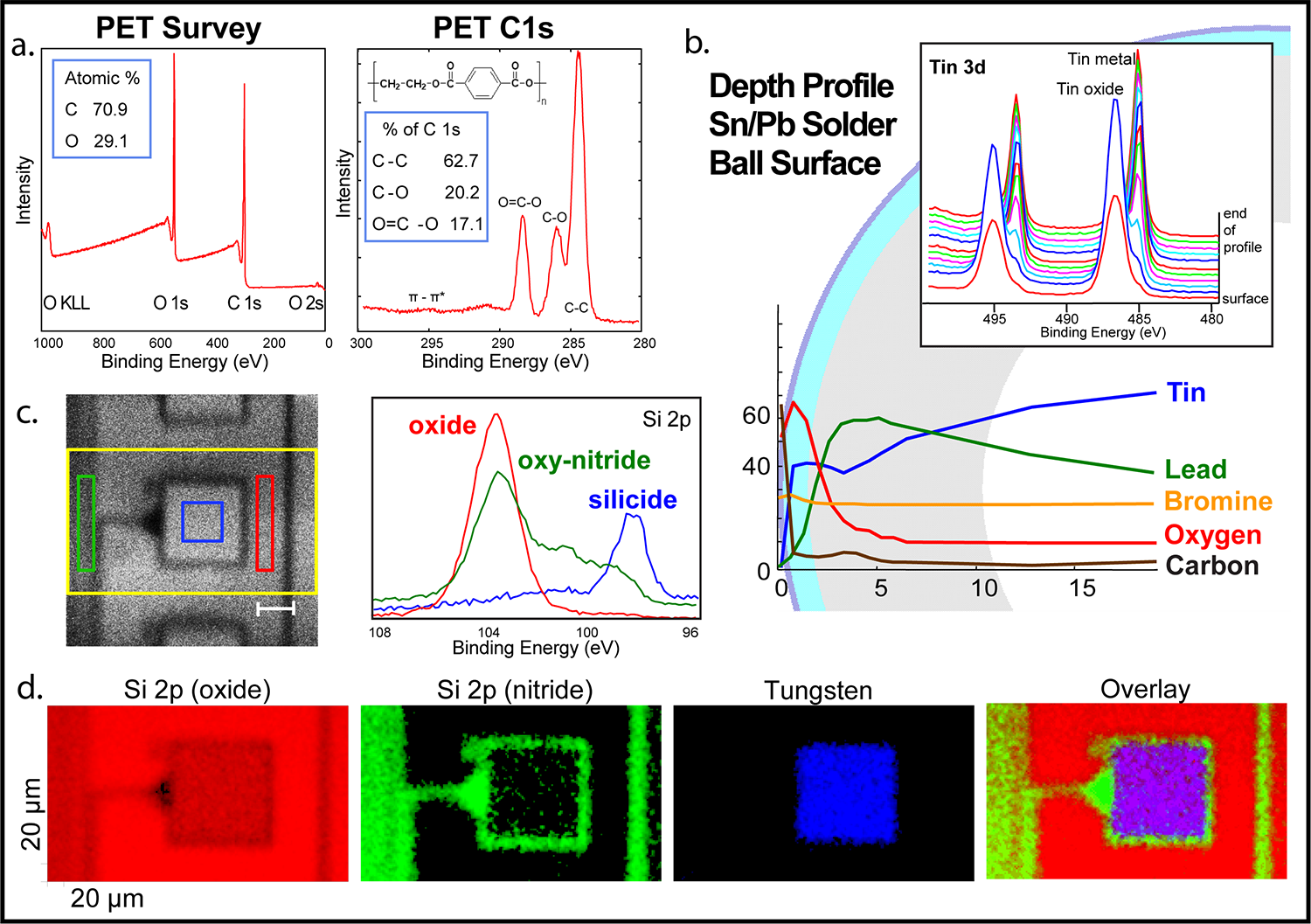

a. XPS Survey and Carbon High Resolution data for PET (Polyethylene Terephthalate). From the survey spectra all elements present at the surface are identified and atomic concentration is calculated. In High Resolution spectra the C-O bonds present can be identified and quantified. b. Ar sputter depth profile of the surface of Sn/Pb solder ball. From atomic concentrations the surface layers can be identified : surface contamination <1nm (dark blue), oxidized layer 2 nm (light blue), lead rich zone >20 nm (grey). The inset shows the Tin high res spectra the oxidized layer can be identified as tin oxide compared to the metallic Tin present in the lead rich zone. c. SXI image of a patterned device marked with three analysis regions. The high resolution Si spectra is color coded for each region oxide (red), oxy-nitride (green), and silicon (blue). d. Chemical mapping of the SXI region from C shows individual elements and species as well as an overlay. Data was mapped with a 10 μm beam.

*All images reproduced from PHI product material.