DICE

Design Innovation and Computational Engineering

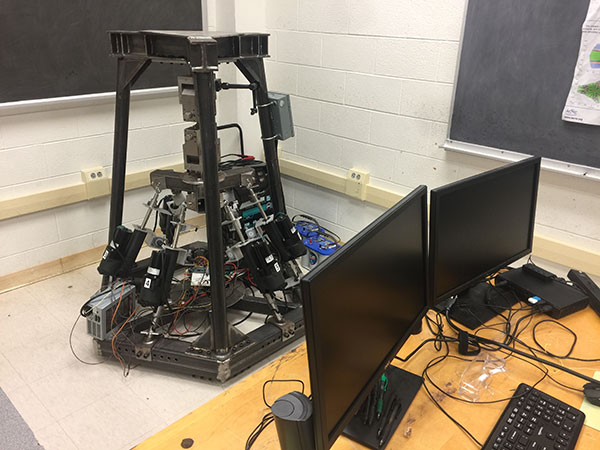

Research themes: The Design Innovation and Computational Engineering (DICE) Laboratory is part of the Clemson Engineering Design Applications and Research (CEDAR) Group at Clemson University. The DICE Lab consists of three research areas. The first is a typical student office space shared with students from other research groups in the CEDAR group. A collaborative work environment is encouraged by intermingling students with different research interests related to engineering design. The second space is being developed into a joint immersive design visualization laboratory enabling virtual design collaboration between geographically distributed sites. The third space is called the Advanced Digital Design (ADD) Laboratory. The ADD laboratory includes 15 different Additive Manufacturing machines, including LOM, FDM, SLA, SLS, Inkjet machines, CNC laser and foam cutting machines, and a custom-built 6-DOF multiaxial testbed designed for high ductility materials called Tiger 66. This is one of four machines in the world for these studies. In addition, research is supported through multiple high-performance GPGPU-enabled computer desktop workstations and access to the Clemson Palmetto cluster.

The DICE Lab uses emerging computational capabilities to advance design and manufacturing capabilities. Our research enables fundamental advances in our ability to design and manage the complexities inherent in designing complex cyber-physical systems with engineered materials. In this environment of Variable, Uncertain, Complex and Ambiguous (VUCA) technologies and constraints, we develop and employ agile design methodologies to enable us to make research contributions in a diverse set of multidisciplinary engineering areas, including:

The DICE Lab uses emerging computational capabilities to advance design and manufacturing capabilities. Our research enables fundamental advances in our ability to design and manage the complexities inherent in designing complex cyber-physical systems with engineered materials. In this environment of Variable, Uncertain, Complex and Ambiguous (VUCA) technologies and constraints, we develop and employ agile design methodologies to enable us to make research contributions in a diverse set of multidisciplinary engineering areas, including:

- The development of computational methods to enhance early state design conceptualization and Tradespace design;

- The use of surrogate models to enable efficient design optimization in nonlinear, mixed continuous-discrete multi-objective systems optimization problems;

- The generation of digital twins to enable intelligent integrated adaptive performance management schemes for automated systems;

- The ability to co-design systems with simultaneous consideration of engineered material systems, shape and geometry optimization, and intelligent control capabilities; and

- The use of in situ reconfiguration of additively manufactured components to reduce and eliminate manufacturing defects.

The DICE Lab enjoys research collaborations with faculty in Mechanical Engineering, Industrial Engineering, Automotive Engineering, Civil Engineering, Chemistry, and the School of Mathematical and Statistical Sciences at Clemson University, as well as with colleagues at Georgia Tech, the Navy Research Laboratory in Washington DC, Los Alamos National Laboratory and the University of Texas system.

Lab facility/equipment:

- Founded 2009

- Total Funding ~3.5M (31 Government Projects, 5 Industry Projects)

- Lab and Office Space – 2143 ft2 (includes space shared with other CEDAR lab groups) Principle Investigator – Cameron J. Turner, Ph.D., PE

- Current Students – 3 Ph.D., 2 M.S./Ph.D., 3 M.S.

- Graduates – 4 Ph.D., 12 M.S. Thesis, 5 MS-Nonthesis

Cameron Turner

Lab Director

(864) 656-2413

cturne9@clemson.edu